The cement industry in Pakistan proceeds to evolve amid climbing design demand and economic fluctuations.

This informative article provides an in-depth check out cement price currently in Pakistan, cost comparisons with preceding months, factors influencing the market, and tendencies across many areas. Whether you are a builder, contractor, or homeowner, being familiar with cement rate in Pakistan is important for budgeting and job preparing.

Exactly what are the Current Prices?

Exactly what is the Cement Amount in Pakistan?

The cement price in Pakistan ranges from PKR one,two hundred to PKR one,400 for every fifty kg bag. This level may well differ determined by the cement brand, area, and transportation expenses. Important city facilities such as Karachi, Lahore, and Islamabad have a tendency to knowledge a little bit higher costs on account of logistical fees and bigger demand from customers for cement.

In this article’s A fast overview of common selling prices:

Brand name Cost for every 50 kg Bag (PKR)

Blessed Cement 1,280

DG Cement one,250

Fauji Cement 1,230

Maple Leaf Cement one,270

Dewan Cement 1,two hundred

What Components Impact The existing Cement Costs?

Many components influencing cement selling prices Enjoy a task:

Gasoline & Electricity Charges: Cement producing is Strength-intense. Fluctuations in oil and gas charges straight impact the cost of cement in Pakistan.

Raw Material Availability: Vital parts which include gypsum, clinker, and limestone are becoming costlier, influencing the cost of cement.

Seasonal Desire: In the course of peak development months (spring and summer months), cement need surges, raising rates.

Currency Trade Rate: Imported raw supplies turn into costlier when the rupee weakens against the dollar.

Government Insurance policies: Obligations, taxes, and import regulations also effect the cement price currently in Pakistan.

These aspects collectively ascertain how cement charges change month by thirty day period across Pakistan.

Cement Price tag in Pakistan: Comprehension the industry Developments

What exactly are the Latest Cement Prices in Pakistan?

The most recent cement price ranges in Pakistan change in between PKR one,200 and PKR 1,four hundred per bag, motivated from the manufacturer, length from production units, and native supply chains. Cement brands in Pakistan like Fortunate Cement, DG Cement, and Fauji Cement preserve reliable top quality, which frequently justifies their top quality pricing.

What Are the Predictions for Cement Charges in the Approaching Months?

The cement industry in Pakistan is anticipated to stay cement price in pakistan under pressure from world fuel rates and inflation. Analysts predict that cement premiums may possibly enhance a little or continue being stable in coming months Unless of course substantial modifications occur in gasoline tariffs or Uncooked substance Value dynamics.

Things that may affect long run pricing:

Submit-election financial reforms

Gas subsidy policies

International commodity prices

A stabilization or reduction in gas costs could lead on to decrease rates as a result of lessened output and logistics expenditures.

How can Need Have an effect on the cost of Cement in Pakistan?

Demand from customers for cement peaks through Energetic building seasons, including March through September. All through these periods, cement fees in Pakistan could climb due to confined source and amplified orders. Conversely, off-time months can see stabilized or a bit diminished rates.

Huge infrastructure and real-estate assignments underway across towns like Lahore, Islamabad, and Karachi continue to add to strong cement demand from customers, pushing the industry toward bigger rates.

Varieties of Cement Out there in Pakistan: Which Should really You decide on?

What exactly are the differing types of Cement Readily available in Pakistan?

Pakistan provides A variety of cement types catering to assorted design jobs:

Ordinary Portland Cement (OPC): The most commonly employed kind of cement for normal properties.

Portland Pozzolana Cement (PPC): Gives improved longevity and resistance to chemical assaults.

Slag Cement: Created utilizing blast furnace slag, perfect for industrial buildings.

White Cement: Aesthetic cement used in tiles, flooring, and decoration.

Hydraulic Cement: Immediately sets when mixed with water, well suited for water-retaining constructions.

Most of these cement provide distinctive roles, and choosing the ideal a single relies on building desires, environmental circumstances, and ideal toughness levels.

Mackenzie Rosman Then & Now!

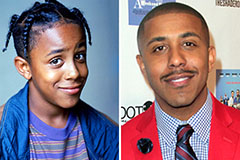

Mackenzie Rosman Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now!